Grinding Machines for Laboratory Materials: A Comprehensive Guide

Grinding is a fundamental process in laboratory operations, involving the reduction of materials into finer particles for various analyses, preparations, and experiments. This article delves into the world of grinding machines specifically designed for laboratory applications, exploring their types, functionalities, and considerations for selection.

Types of Laboratory Grinding Machines

Laboratory grinding machines encompass a diverse range of equipment, each tailored to specific particle size reduction requirements.

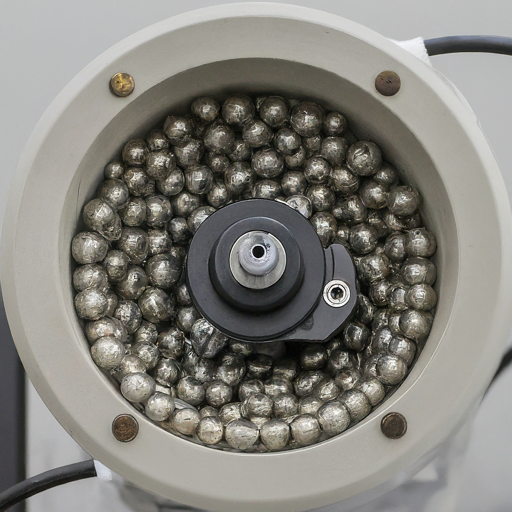

Ball Mills

Principle: Utilize impact and attrition forces exerted by grinding media (balls) within a rotating chamber.

Applications: Suitable for grinding a wide range of materials, from soft to hard, dry or wet. Types: Planetary ball mills, vibration ball mills, and horizontal ball mills offer varying levels of energy input and grinding efficiency.Mixer Mills

Principle: Combine impact and grinding through high-frequency vibration.

Applications: Ideal for mixing and grinding dry or wet samples, including brittle materials. Advantages: Fast and efficient, suitable for small sample volumes.

Planetary Mills

Principle: Employ centrifugal and planetary forces to generate high-energy impact and grinding. Applications: Suitable for producing fine particles, often used in materials science and nanotechnology.

Advantages: High efficiency, ability to handle various materials, and versatility.Mortar and Pestle

Principle: Manual grinding using a mortar and pestle.

Applications: Suitable for small-scale sample preparation and qualitative analysis.

Advantages: Simple and inexpensive, ideal for preliminary sample reduction.Knife Mills

Principle: Use rotating blades to cut and shear materials.

Applications: Suitable for soft to medium-hard materials, often used in food and pharmaceutical industries. Advantages: Fast sample preparation, minimal heat generation.Cryogenic Mills

Principle: Grind materials at cryogenic temperatures to improve particle size reduction and prevent material degradation. Applications: Suitable for heat-sensitive materials and achieving ultrafine particle sizes.

Advantages: Preserves material integrity, enhances grinding efficiency.Factors to Consider When Selecting a Grinding Machine

Sample properties: Material hardness, moisture content, and desired particle size distribution.

Sample volume: Determine the required capacity of the grinding machine.

Grinding efficiency: Consider the machine's ability to achieve desired particle size in a reasonable time.

Contamination risk: Evaluate the machine's design and materials to minimize contamination.

Safety features: Prioritize safety features like emergency stops and enclosures.

Cost: Balance equipment cost with operational expenses and maintenance requirements.

Ease of use and maintenance: Consider the machine's user-friendliness and cleaning procedures.Laboratory Grinding Machine Applications

Laboratory grinding machines have diverse applications across various industries:

Materials science: Preparing samples for characterization and analysis.

Pharmaceutical industry: Grinding active pharmaceutical ingredients and excipients. Chemical industry: Processing solid samples for analysis and synthesis.

Environmental science: Preparing samples for contaminant analysis.

Food industry: Grinding samples for quality control and product development.

Geology and mineralogy: Preparing samples for mineral analysis and characterization.Selecting the appropriate grinding machine for laboratory applications requires careful consideration of various factors. By understanding the different types of grinding machines, their capabilities, and the specific requirements of your laboratory, you can make an informed decision to enhance your research and development processes.

laboratory grinding machine, ball mill, grinding equipment, laboratory equipment, materials science, pharmaceutical, chemical, environmental, food, geology

Would you like to delve deeper into specific types of grinding machines or explore the challenges associated with grinding different materials?