Inorganic Pigment Grinding Machine: A Comprehensive Guide

Úvod

Inorganic pigments, essential coloring agents in various industries, require precise particle size reduction for optimal performance. Grinding machines play a pivotal role in achieving the desired particle characteristics. This article explores the types of grinding machines suitable for inorganic pigments, their applications, and factors to consider when selecting the right equipment.

Types of Grinding Machines for Inorganic Pigments

Several types of grinding machines are commonly used for processing inorganic pigments, each with its specific characteristics and applications.

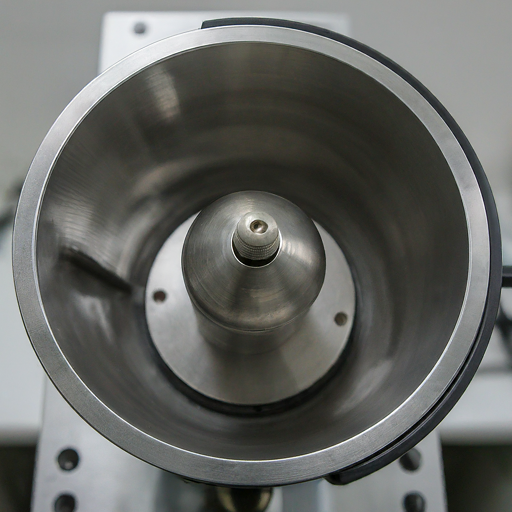

Ball Mills

Principle: Utilize impact and attrition forces exerted by grinding media (balls) within a rotating chamber.

Applications: Suitable for grinding a wide range of inorganic pigments, including oxides, carbonates, and sulfides.

Advantages: Versatile, capable of achieving fine particle sizes, and suitable for both wet and dry grinding.Attritors

Principle: Employ high-speed impellers to create a turbulent media-powder mixture, resulting in particle size reduction.

Applications: Effective for grinding hard-to-grind inorganic pigments and achieving fine particle sizes.

Advantages: High efficiency, rapid grinding, and suitable for large-scale production.Jet Mills

Principle: Utilize high-velocity gas or air jets to collide and pulverize particles.

Applications: Suitable for producing ultrafine inorganic pigment powders, especially for applications requiring high color intensity and dispersion.

Advantages: High-energy grinding, minimal contamination, and suitable for heat-sensitive materials.

Hammer Mills

Principle: Utilize rotating hammers to strike and crush materials.

Applications: Suitable for coarse grinding of inorganic pigments, often used as a primary reduction step.

Advantages: High capacity, robust construction, and suitable for handling large feed sizes.Factors to Consider When Selecting a Grinding Machine

Pigment Properties: Consider the hardness, abrasiveness, and desired particle size distribution of the inorganic pigment.

Production Scale: Assess the required throughput and batch size.

Contamination Control: Evaluate the need for inert atmospheres or other measures to prevent contamination.

Energy Efficiency: Consider the machine's power consumption and overall efficiency.

Safety Considerations: Ensure the grinding machine has appropriate safety features.

Maintenance Requirements: Evaluate the ease of cleaning, component replacement, and overall upkeep.Applications of Inorganic Pigment Grinding

Inorganic pigments are used in a wide range of industries, including:

Paint and Coatings: Producing pigments for paints, varnishes, and coatings.

Plastics: Coloring plastic materials.

Textiles: Dyeing fabrics with pigments.

Printing: Producing pigments for ink and toner.

Cosmetics: Coloring cosmetics and personal care products.

Ceramics: Coloring ceramic products.Conclusion

Selecting the right grinding machine for inorganic pigments is crucial for achieving optimal color performance and product quality. By carefully considering the factors outlined in this article, manufacturers can ensure efficient and effective grinding operations.

Keywords: inorganic pigment grinding machine, pigment grinding, grinding equipment, ball mill, attritor, jet mill, hammer mill, pigment, color, paint, coatings, plastics, textiles, printing, cosmetics, ceramics

Would you like to delve deeper into specific types of grinding machines or explore the challenges associated with grinding different inorganic pigments?