The Laboratory Ball Mill: A Versatile Tool in Industrial Processes

The laboratory ball mill, a cornerstone in materials processing, is a device that reduces particle size through repeated impact and attrition. Its versatility, coupled with its ability to handle a wide range of materials, makes it an indispensable tool across diverse industries.

Fundamental Principles of Ball Milling

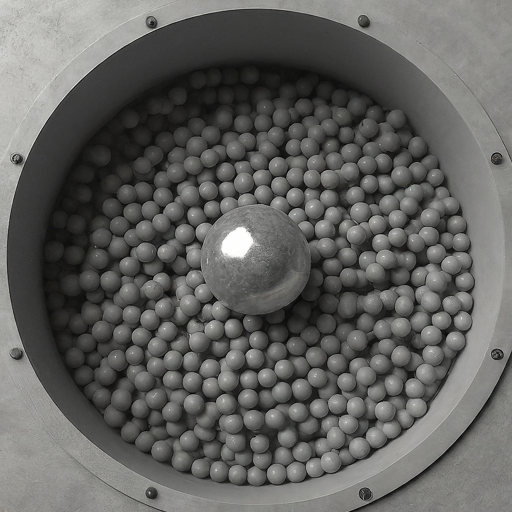

The operation of a ball mill is relatively straightforward yet profoundly effective. A cylindrical chamber, often made of hardened steel or ceramic, is filled with grinding media—typically ceramic or steel balls. As the chamber rotates, the grinding media cascade, impacting the material and reducing it to finer particles.

Applications Across Industries

The laboratory ball mill finds applications across a vast spectrum of industries due to its versatility and efficiency.

Materials Science and Metallurgy

Powder Metallurgy: Producing metal powders for various applications, including additive manufacturing and composite materials.

Material Characterization: Preparing samples for analysis techniques like microscopy, spectroscopy, and chromatography.

Alloy Development: Creating homogeneous alloy compositions for research and development.

Pharmaceuticals and Biotechnology

Drug Development: Grinding active pharmaceutical ingredients (APIs) to improve bioavailability.

Excipient Preparation: Producing fine powders for tablet and capsule formulations.

Nanoparticle Synthesis: Creating nanoparticles for drug delivery and imaging. Ceramics and Refractories

Raw Material Preparation: Grinding and homogenizing ceramic and refractory materials.

Pigment Dispersion: Preparing pigment dispersions for ceramic glazes and coatings.

Powder Metallurgy: Producing ceramic powders for advanced ceramics.Environmental Science

Soil and Water Analysis: Preparing samples for chemical analysis and contaminant detection.

Waste Management: Processing solid waste for recycling and disposal.

Pollution Control: Analyzing environmental samples for pollutants.Other Industries

Cosmetics: Producing fine powders for makeup and skincare products.

Food Industry: Grinding and homogenizing food materials for analysis and product development.

Energy: Processing materials for battery and fuel cell applications. Source icon

Factors Affecting Grinding Performance

Several factors influence the efficiency and outcome of ball milling:

Grinding Media: The type, size, and quantity of grinding media significantly impact particle size reduction.

Mill Speed: Higher speeds generally lead to finer particles but can also generate heat and reduce grinding media life.

Grinding Time: The duration of the grinding process affects the final particle size distribution.

Material Load: The amount of material loaded influences grinding efficiency and prevents overloading.

Chamber Design: The chamber's geometry and material can affect grinding performance.Advancements in Ball Milling Technology

The field of ball milling is continually evolving. Modern advancements include:

High-Energy Ball Mills: For producing ultrafine particles and nanomaterials. Planetary Ball Mills: Offering more aggressive grinding through planetary motion.

Cryogenic Ball Milling: Grinding materials at low temperatures for improved results.

Inert Atmosphere Ball Mills: For processing air-sensitive materials.The laboratory ball mill stands as a versatile and indispensable tool in modern industry. Its ability to handle a wide range of materials and produce fine particles with precision makes it an essential equipment for research, development, and production processes.

Source icon

Would you like to delve deeper into specific applications or explore the challenges associated with ball milling?