New Metal Material Grinder: A Comprehensive Guide

Introduction

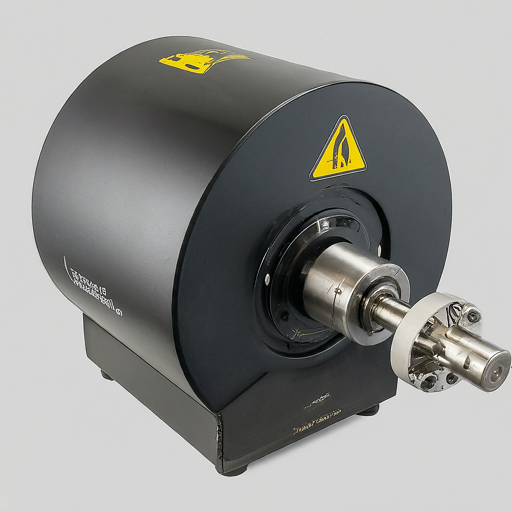

The field of metal materials is constantly evolving, with new alloys and composites emerging for diverse applications. Grinding machines play a pivotal role in processing these materials, ensuring precise particle size reduction and facilitating subsequent manufacturing processes. This article explores the latest advancements in metal material grinders, their applications, and factors to consider when selecting the right equipment.

Types of Grinding Machines for Metal Materials

Several types of grinding machines are commonly used for processing metal materials, each with its specific characteristics and applications.

Source icon

Ball Mills

Principle: Utilize impact and attrition forces exerted by grinding media (balls) within a rotating chamber.

Applications: Suitable for a wide range of metal materials, including ferrous and non-ferrous metals.

Advantages: Versatile, capable of achieving fine particle sizes, and suitable for both wet and dry grinding.Attritors

Principle: Employ high-speed impellers to create a turbulent media-powder mixture, resulting in particle size reduction.

Applications: Effective for grinding hard-to-grind metal materials and achieving fine particle sizes.

Advantages: High efficiency, rapid grinding, and suitable for large-scale production.

Jet Mills

Principle: Utilize high-velocity gas or air jets to collide and pulverize particles.

Applications: Suitable for producing ultrafine metal powders for specific applications.

Source icon

Advantages: High-energy grinding, minimal contamination, and suitable for heat-sensitive materials.

Source iconHammer Mills

Principle: Utilize rotating hammers to strike and crush materials. Applications: Suitable for coarse grinding of metal materials, often used as a primary reduction step.

Advantages: High capacity, robust construction, and suitable for handling large feed sizes.Recent Advancements in Metal Material Grinders

Nanotechnology: Grinding machines have been adapted to produce nano-sized metal powders for advanced materials applications.

Automation: Increased automation has improved efficiency and precision in grinding operations.

Energy efficiency: Newer models incorporate energy-saving technologies to reduce operating costs.

Material compatibility: Grinding machines are designed to handle a wider range of metal materials, including exotic alloys and composites.Factors to Consider When Selecting a Grinding Machine

Material properties: The type of metal material, hardness, and desired particle size distribution.

Production scale: Batch size and desired throughput.

Particle size requirements: The target particle size range for the application.

Contamination control: The need to minimize contamination during the grinding process.

Energy efficiency: The machine's power consumption and overall efficiency.

Safety considerations: Equipment safety features and operator protection.

Maintenance requirements: Ease of cleaning, component replacement, and overall upkeep.Applications of Metal Material Grinding

Metal material grinding is essential in various industries, including:

Powder metallurgy: Producing metal powders for sintering and other manufacturing processes.

Additive manufacturing: Preparing metal powders for 3D printing.

Metallurgy: Processing metal materials for alloying and refining.

Electronics: Grinding metal materials for electronic components.

Aerospace: Processing metal powders for aerospace components.Selecting the right grinding machine for metal materials is crucial for achieving desired properties and optimizing production processes. By carefully considering the factors outlined in this article, manufacturers can ensure efficient and effective grinding operations.

Keywords: new metal material grinder, grinding machine, metal material, powder metallurgy, ball mill, attritor, jet mill, hammer mill, particle size reduction, manufacturing

Would you like to delve deeper into specific types of grinding machines or explore the challenges associated with grinding different metal materials?